29.06.2023

The future is circular

As we transition to electromobility, there’s a growing need to close material cycles. The road ahead leads us further away from the outdated “take, make, waste” principle and towards circularity. Only when we reach this destination will our approach to sustainability be complete. This is why the BMW Group is working on keeping the resources for vehicles in a closed-loop cycle.

To protect and preserve the environment, to reuse valuable resources multiple times and to ensure that nothing ends up going to waste – this is what we understand as circular economy.

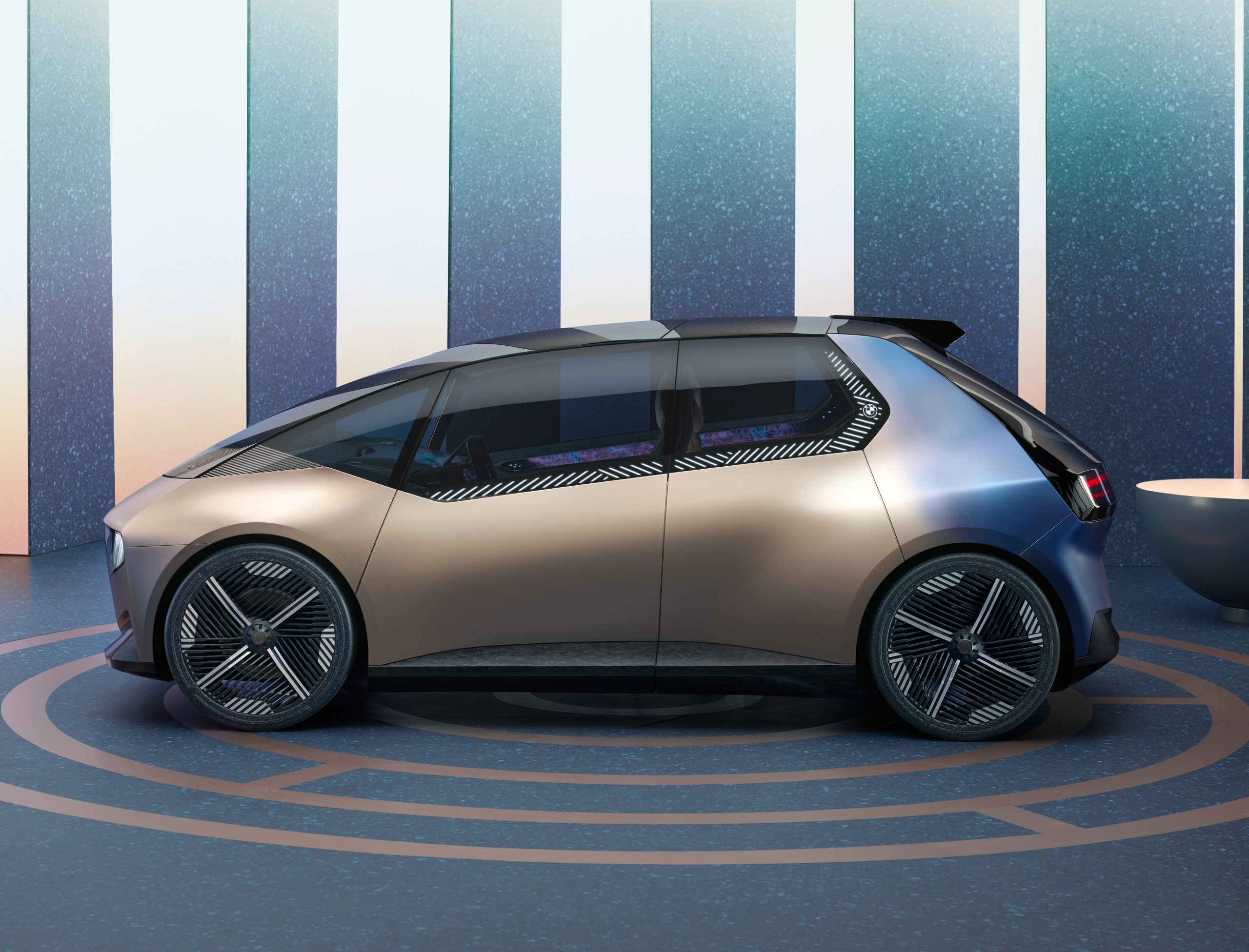

The BMW i Vision Circular shows how a compact, all-electric vehicle focused on sustainability and luxury could look in the future. The principles of the circular economy shaped this vision of the future, in which vehicles are manufactured entirely from secondary materials and are 100% recyclable.

What does the BMW i Vision Circular represent?

The BMW i Vision Circular is based on four principles: RE:THINK, RE:DUCE, RE:USE and RE:CYCLE. They embody both a new way of thinking and acting. This starts with sourcing and procuring resources in a sustainable manner. And it continues by fostering innovative spirit, partnership, transparency and monitoring. To close material cycles has become a mission within the BMW Group. Our determination is evidenced by our “Secondary First” approach.

RE:THINK

Our engineers and circularity experts left no stone unturned when designing the BMW i Vision Circular and scrutinised every detail of the car in line with the RE:THINK principle. The visionary vehicle and how it could be produced – together with all material cycles – were re-imagined from the ground up and tirelessly optimised.

RE:DUCE

Less is more: the RE:DUCE principle involves reducing whatever we use, wherever we can – for example, materials. The BMW i Vision Circular exemplifies this principle with greatly reduced manual controls that have been replaced by purely digital human-machine interfaces. This not only makes the vehicle lighter and helps to protect the environment, but it also reduces costs and helps the driver concentrate even more on what’s important.

RE:USE

Remanufacture and redesign of certain vehicle modules can help extend the life cycle. That’s the aim of the RE:USE principle. It’s for this reason that the connections in the BMW i Vision Circular are all comparatively easy to remove, making it simple to replace certain materials and components. This also allows our engineers to constantly refresh and re-imagine the vehicle.

RE:CYCLE

The RE:CYCLE principle focuses on using recycled materials, which can then be reused again at the end of the product’s or various parts life cycle. Our material researchers therefore selected a manageable number of mono-materials to make up the components of the BMW i Vision Circular, with detachable connections allowing various parts to be quickly and easily dismantled at a later date.

Circularity needs innovation

Innovation is the key to reaching a circular economy. After all, real circularity can only work with the right tools, which is why the BMW Group continues to explore new methods and strategies to keep disused vehicles and their components in the resource cycle. For example, we have recently begun a pilot project with BASF and the ALBA Group aimed at increasing the recycling of vehicle plastics. New components and systems must also be designed to be fully recyclable.

Reuse valuable resources

The circular economy requires a new way of thinking, particularly in terms of where we get our raw materials from and how we use them. In the BMW Group, we’re minimising waste production along the entire value chain whilst also improving our recycling processes and using secondary materials wherever possible.

More about the report and exciting videos on i Vision Circular can be found here.