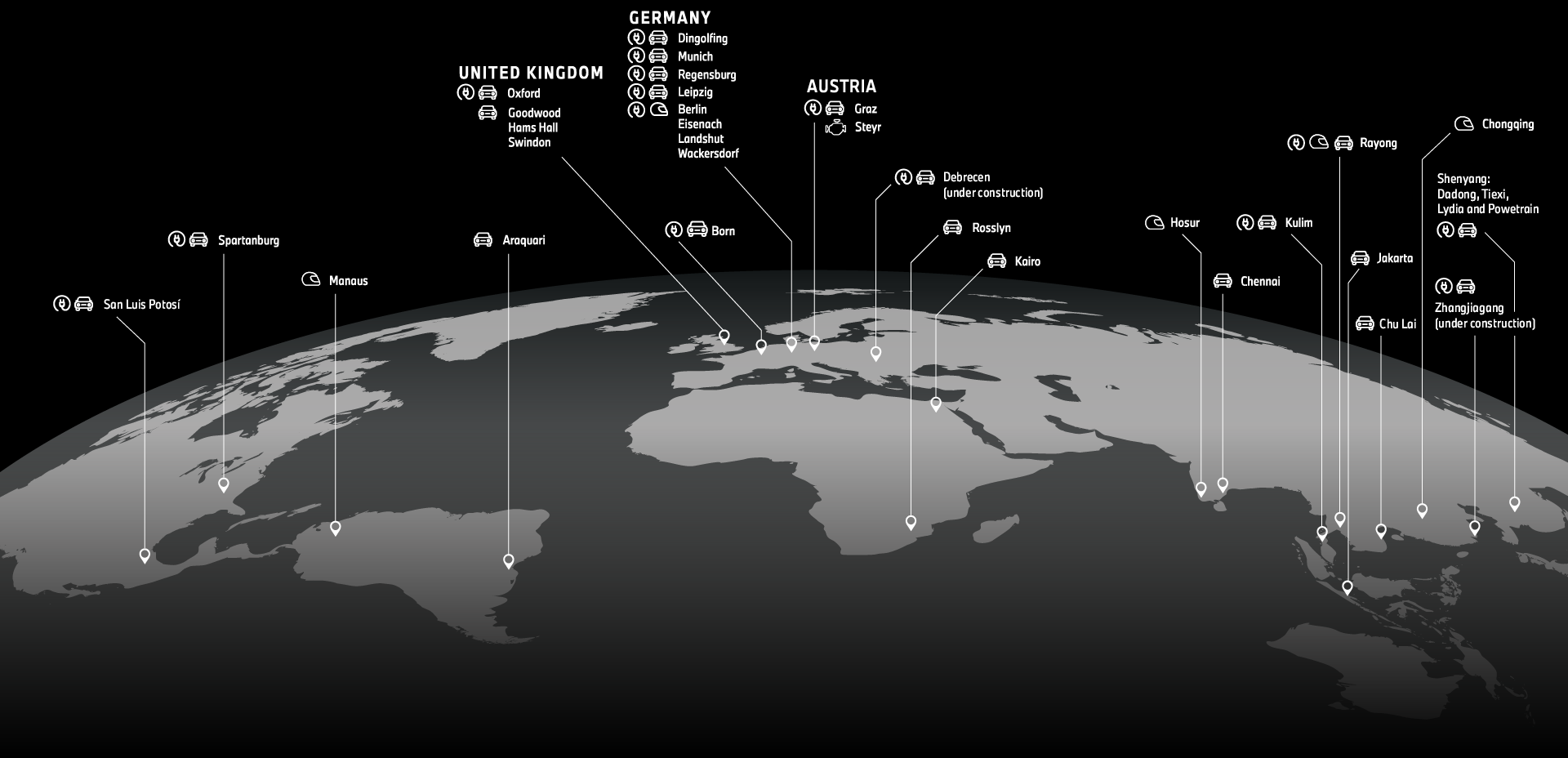

Production sites worldwide

The BMW Group’s production network is home to a wealth of expertise – at over 30 production sites worldwide. Come and visit us at selected locations worldwide and experience production.

Plant Berlin

The BMW Group’s premium motorbikes roll off the production line in the capital. But not only the motorbikes themselves, but also their production is spectacular: more than 2,200 employees from over 20 nations work hand in hand, supported by state-of-the-art technology, to produce high-quality bikes. Visitors also experience the unique insights: The BMW Group Plant Berlin offers public plant tours.

Go to Berlin Plant TourPlant Dingolfing

The BMW Group plant in Dingolfing is the largest vehicle plant of the BMW Group in Europe. The plant site measures 2.8 million square metres. Around 17,000 employees ensure smooth production processes – and pave the way for the mobility of tomorrow. Today, the site is already the showcase for automotive topics of the future. This is primarily due to the BMW iX, which has been rolling off their production line since July 2021: It is fully electric, fully networked and drives automatically. Series production of the sixth BMW 7 Series generation began in Dingolfing in July 2022. A visit to the BMW Group plant in Dingolfing is only available to special stakeholders of the site and needs to be arranged in advance. Tours for private individuals and corresponding registrations are not planned until further notice.

Plant Landshut

At the BMW Group plant in Landshut, around 3,500 employees manufacture, among other things, components for the pioneering BMW i models, i.e. vehicles with partially or fully electric propulsion systems. With future-oriented technologies, the plant plays the role of an innovation-driver as an in-house component production facility. Day after day, the employees ensure that a piece of Landshut’s innovative power is in almost every BMW, MINI and Rolls-Royce, as well as in many BMW motorbikes. The BMW Group Plant Landshut is a target group location that offers its tour formats for trade visitors and closed groups. Public tours are therefore not bookable.

Plant Leipzig

The BMW Group Plant in Leipzig is one of the most innovative automotive factories in the world. The central building designed by Zaha Hadid, one of the most famous modern architects, is unique. Around 1,000 vehicles roll off the production line every day. Also, starting from 2024, the entire process chain of high-voltage battery production will be shown here. The BMW Group Plant Leipzig offers public Plant Tours where visitors can experience production at this location.

Go to Leipzig Plant TourPlant Munich

The BMW Group plant in Munich is the main plant of the BMW Group. It is located in the north of Munich, in the immediate vicinity of the corporate headquarters, the BMW Museum and BMW Welt. Around 8,000 employees from over 50 nations work at this site. Vehicles and engines have been produced in the heart of Munich since 1922 –and around eleven million premium cars now roll off its production line. As early as 2023, at least half of all vehicles from Munich are to be equipped with an electric drive. The BMW Group Plant Munich is located in the immediate vicinity of the BMW Group headquarters, the BMW Museum and BMW World. Combination offers therefore attract visitors not only to the main plant, but also to this surrounding attractions.

Go to Munich Plant TourPlant Oxford

The BMW Group Plant Oxford is the home of the MINI. The legendary and popular car has been manufactured here for more than 20 years. The plant is also known as the laboratory of the future: it only takes around 22 hours to complete a vehicle from the delivery of its component materials. MINI Plant Oxford offers public plant tours. Before or after the tour, there is the opportunity to learn even more about the fascinating history of MINIs in the MINI Museum.

Go to Oxford Plant TourPlant Regensburg

A new BMW leaves the Regensburg plant every 57 seconds – totalling around 1,000 per working day. Production started in 1986 with 200 cars a day and has continuously increased. Today, around 9,000 employees are working on this success story, which continues with its electrified models. With the plug-in hybrid variants of the BMW X1 and the BMW X2, the first electrified Regensburg models are already on the road. They combine the best of both worlds – a combination of a combustion engine and an electric motor. The BMW Group Plant Regensburg is a target group location that offers its tour formats for trade visitors and closed groups. Public tours are therefore not bookable.

Plant Rosslyn

The South African plant in the Rosslyn district was the BMW Group’s first international location in 1973. Within a short time, the plant developed into a flexible, efficient and sustainable production facility. Currently, 3,000 employees in Rosslyn primarily build the sixth generation of the BMW X3 series with an annual production volume of around 75,000 vehicles. The models produced in Rosslyn are destined for customers in the USA, Taiwan, Japan, Singapore, New Zealand and Australia, among others. The BMW Group Plant Rosslyn offers public plant tours.

Go to Rosslyn Plant TourPlant San Luis Potosí

The San Luis Potosí plant is the first BMW Group location in Mexico and is considered a pioneer in sustainability and digitalisation. This is due to the BMW Group’s first paint shop that is completely free of process wastewater and the power supply, which is completely generated from renewable energies and will be 100 per cent CO2-free in the future. At the same time, Industry 4.0 enables a rapid response to new production variants and volumes. Around 3,000 employees mainly produce the BMW 3 Series G20 there. The BMW Group Plant San Luis Potosí offers public plant tours.

Go to San Luis Potosí Plant TourPlant Spartanburg

The BMW Group Plant Spartanburg in the US state of South Carolina is home to the BMW X model family. Every day, 11,000 employees produce more than 1,500 vehicles on the approximately seven million square metre plant site. The production facility makes a significant contribution to the international success of the BMW Group: Around 60 per cent of the vehicles produced in Spartanburg are destined for export to 120 different countries. The BMW Group Plant Spartanburg ffers public plant tours.

Go to Spartanburg Plant TourPlant Steyr

At the BMW Group’s largest engine plant in its global production network, around 4,400 people develop and produce the mobility of the future every day – from innovative diesel and gasoline engines to sustainable e-mobility components and, from 2025, next-generation electric vehicles. Over 1 million engines and more than 10 million core engine components leave the Steyr plant every year. They power around half of all BMW and MINI cars worldwide. “A heart from Steyr” is a promise of quality for automobiles of all kinds. The BMW Group Plant Steyr is a target group location that offers its tour formats for trade visitors and closed groups. Public tours are therefore not bookable.

All BMW Group Locations at a glance